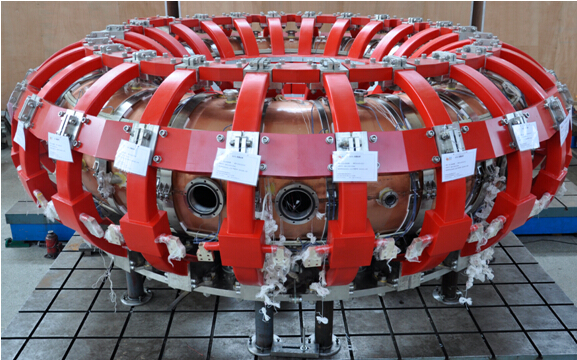

The main machine of KTX Reverse Field Pinch came into existence with its bright dazzling red color on March 30 in front of its creators, scientists and engineers from University of Science and Technology of China (UTSC), ASIPP and KEYE Company after the PF coils, feed-back control coils, toroidal coils, conductive shell and other key components were put together. The follow-up commissioning of the openable double C vacuum chamber proves the machine is not only beautiful but also wonderful.

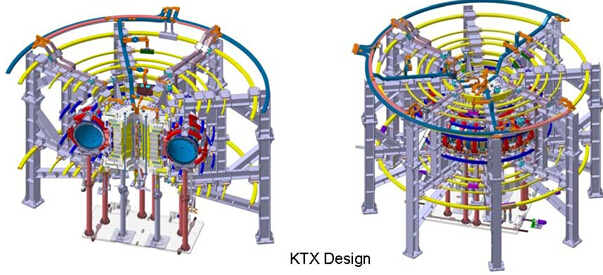

KTX, which stands for ¡°Keda Torus for eXperiment¡±, is a new reverse field pinch (RFP) device, with main parameters between FRX and MST. Its design and R&D is a China domestic ITER-related research project, undertaken jointly by USTC, ASIPP and manufactured and assembled by KEYE Company.

The mission of KTX is to explore the plasma profiles of fusion commercial reactor, to study the ¡°self-organization¡± behavior of magnetic confinement plasma, including dynamo and single spiral phenomena. The project was launched in 2011, will be completed this year.

Given the short time scale and technical difficulties, Keye Company team, in cooperation with USTC and ASIPP, conducted a large amount of R&D in three years; they have rolled out nearly 10000 engineering drawings.

|

Main parameters of KTX: |

|

|

Major radius |

1.4m |

|

Minor radius |

0.4m |

|

Magnetic field in Plasma Center |

0.7T |

|

Toroidal field coil |

24 |

|

Ohm field coils |

26 |

|

Equilibrium field coil |

12 |

|

Feed-back control coil |

104 |

|

Maximum plasmas current |

1MA |

|

Plasma density |

2¡Á1019m-3, |

|

Electron Temperature |

600eV |

|

Plasma discharge time |

30-100ms |

On KTX KEYE together with ASIPP developed an innovative formation technology of 1.5mm thin conductor with fast feed-back control, less than 8% error field and on-site flexible controllable baking. At the same time they adopted double C openable vacuum chamber structure design. These would boost plasma real time feedback and enhance maintenance and upgrade efficiency in the future, thus to increase the device operation time and decrease its maintenance cost.

Other key technologies developed include the seamless formation technology of large type-shape vacuum chamber with R=1.4m, r=0.4m and large coils with D=7.06m. The quality design and R&D of TF, PF, conductive shell, feedback control coils and supports have laid a sound basis for the manufacture of the KTX main machine.

¡°KTX will give its first plasma charge in June,¡± says Prof LIU Wandong, chief engineering director, also Dean of Modern Physics Department of USTC. Liu, a well-know plasma physicist himself, is excited about the KTX experiments and results it may produce, believing ¡°KTX RFP will be a new way to explore fusion energy¡±.